From the Hi-Lift® Jack website.

The Hi-Lift® Jack is a rugged, highly versatile jack that puts you

in command of situations requiring lifting, pushing, pulling, winching,

and clamping. Although light in weight and easy to maneuver, the Hi-Lift®

Jack offers a rated lifting capacity of 2 1/3 tons (2114.74kg).

Most of us that do any off roading or even landscaping, I have a buddy

that uses his for his fencing company, he used to make these Jacks. If

yours is anything like mine you have used it for more things than just

working on the vehicle off road. We carry them on the front bumper, rear

bumper, roof racks, the hood, etc… All the time exposing them to

the weather, dirt, sand and then hope that they work when we really need

them. Well mine has seen many years of being left outside. It has gone

from being a nice read color to kind of a molted rusty brown. I figured

it was time to give the jack an overhaul and see if anything is really

wearing out on it. Now I haven’t touched the jack since the start

of last years Hurricane season down here, of which the jack weathered

everyone outside. I wasn’t really confident that the jack actually

operated smoothly. I did grease it up really good last time I put it on

the front, and I do carry grease and WD-40 to loosen it up, so I wasn’t

to worried about having to use it. So I pulled the jack off the front

bumper and gave it a try. Things were looking up since it actually worked

fairly smoothly. So now was time to take it apart. If you need any additional

parts other than the FIX-IT-KIT, you can call Hi-Lift® Jack Company

at (800) 233-2051, or (812)384-4441 from outside the USA.

Installation: |

1.

For those of you that still have it attached. Remove the foot piece

from the bar by pulling out the cotter pin. I have a regular snap

pin in mine since I store the foot piece in the back of the Jeep.

You will need a pair of pliers for this. |

|

2.

Remove the Top Clam-Clevis by removing the Top Clam-Clevis Bolt

with a 3/4” combo wrench and a 3/4” socket. It’s

easier if you can clamp this in a vice, but I managed to lock a

leg around it and get it to come free.

|

|

3. Remove the

bar from the Running Gear assembly by just running it all the way

to the ground and just pulling the bar out. |

|

4. Disassemble

the Running Gear assembly. |

5. Remove the

Handle by pulling out the cotter pin from the Handle Socket. You

will need a pair of pliers for this. |

|

6. Remove the

Climbing pins using a drift punch and a hammer to drive the cross

pins out. |

|

7. Remove the

Climbing Pins and Climbing Pin Springs. Be careful with the springs

since they will find the most inconvenient place in the garage when

they pop out. |

|

8. Remove the

Cab Screw and washer holding the Reversing Latch with a 1/2”

Socket. |

|

| 9. Remove the Reversing Switch

Cam Bar and Spring. |

|

|

|

10. Remove

the Hi-lift® Shear Bolt that holds the Pitman to the Small runner.

This will require a 1/2" socket and combo wrench. |

|

11. Remove

the Hex bolt that holds the Handle socket to the Large Runner. Use

a 11/16" and 5/8" combo wrench. |

|

12.

Tap out the Pitman Pin that holds the Pitman to the Handle Socket. |

|

|

13. Lets not

forget the handle. Remove the Handle Spring Clip from the Handle.

If yours is like mine, you won’t need to try very hard, it

just kind of snaps apart and falls off. |

|

14. Now that

you have everything apart, take a close look at the Climbing Pins,

Climbing Pin Springs, and the Hi-Lift® Shear Bolt. My springs

were rusty, but didn’t seem to have lost any force. The Climbing

Pins were a little rusty, so I hit them with the wire wheel. Note:

Do not hold the pin with your finger, it will most likely end up

with you trying to figure out where the pin went after you drop

it. I looked at the Hi-Lift® Shear Bolt and saw that it was

bent. Obviously, after all the years of use I had managed to bend

it, I probably came pretty close to shearing it at one time. With

this being bent, even though the springs and Climbing Pins looked

good, I won’t take the chance for safety reasons. If I had

stressed 1 part, I may have others that are stressed. I will replace

all the parts. |

|

|

15. I looked

at all the parts where pins or bolts go through and made certain

I didn’t have any burrs, or obvious damage. |

16. Take a

wire wheel and clean off all of the dust, dirt, grime and rust.

I was able to get inside the holes on the bar with a dremel wire

wheel. You might be able to get in there with a small wire brush. |

17. Wipe down

the jack with some degreaser and alcohol to clean off any foreign

material. |

18. Spray a

coat of rust converter on the jack pieces to catch any rust that

you weren’t able to get with the wire wheel. |

| 19. I lightly sanded the jack

pieces again to get rid of any of the inevitable dust/ fuzzy’s

that seem to be attract to anything freshly painted. I then sprayed

a coat of red paint on the jack. Once this dried, it was time to reassemble. |

|

| |

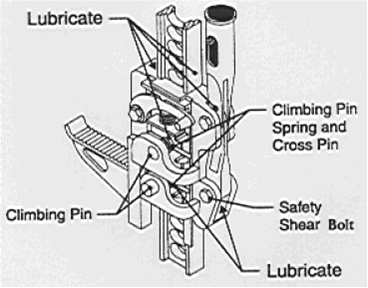

NOTE: When

you reassemble the Hi-Lift® Jack you will need to lubricate the

following parts:

Lubricate the Jack using white lithium grease, light penetrating oil,

or a silicon or Teflon spray at the following points:

Steel Bar:

Keep the front and back edges of the steel standard (bar) lightly

lubricated and free from dirt and rust.

Pitman Pin:

Keep the pitman pin lubricated or it will damage the handle socket

and pitman.

Shear bolt:

Keep the shear bolt clean and lubricated to keep it from wearing out.

Climbing Pins and Springs:

Keep both climbing pins and springs lubricated and free from dirt

and rust.

I found that in addition to what Hi-Lift® recommends you should

also lubricate the Hex Bolt and Cap Screw w/ Washer. I also put a

little grease on the insides of the Large and Small Runner.

Do not use motor oil or grease to

lubricate the jack.

|

| |

| Reassembly: |

|

| 1. Assemble the Running Gear

first. Lubricate and tap the Pitman Pin that holds the Pitman to the

Handle Socket in. Now mine was a little loose after cleaning up all

of the rust on the old one. Don't worry, once it's installed in the

large runner it can't come out. |

|

|

2. Lubricate and install

the Reversing Switch Cam Bar and Spring into the Large Runner. |

|

| 3. Slide the spring inside

of the large runner. |

|

| 4. To get the cam bar to slide

into position you will need to pry back the spring. I used a flat

tip screwdriver through the center of the bar to pry back the spring. |

|

|

5. Install the Cab Screw

and washer holding the Reversing Latch with a 1/2” Socket. |

|

|

6. Install the Climbing

Pin and Climbing Pin Spring. Install the spring in the larger runner. |

|

| 7. Insert the climbing pin

into the larger runner. The beveled side of the climbing pin goes

towards the top (towards the reversing latch). |

|

8. Install the Cross Pins

into the Climbing pins using a drift punch and a hammer. Be careful

you don't catch the wire of the spring. Once you have the cross

pin in you can rotate the spring until just the bottom is under

the cross pin. |

|

| 9. Install the Climbing Pin

and Climbing Pin Spring into the small runner. The climbing pin bevel

goes towards the front (top) of the small runner as position in the

picture. |

|

| 10. Install the Cross Pins

into the Climbing pins using a drift punch and a hammer. Be careful

you don't catch the wire of the spring. Once you have the cross pin

in you can rotate the spring until just the bottom is under the cross

pin. |

|

| 11. Install the Hex bolt that

holds the Handle socket to the Large Runner. Use a 11/16" and

5/8" combo wrench. The bolt goes through from the reversing latch

side this will ensure that the latch clears the bolt. |

|

|

| 12. Position the small runner

over the Reversing Switch Cam Bar. There is a notch in the small runner

underneath the cross pin that the bar slides through. push the small

runner up enough that it can slide into the notch in the large runner. |

|

|

| 13. Install the Hi-lift®

Shear Bolt that holds the Pitman to the Small runner. This will require

a 1/2" socket and combo wrench. The bolt goes through from the

reversing latch side. |

|

| The assembled running gear. |

|

14. Install the Handle in

the Handle Socket and install the cotter pin. |

|

| The bar may have two different

ends to it. |

Bottom end |

Top end |

15. Install the Clam-Clevis

by installing the Top Clam-Clevis Bolt with a 3/4” combo wrench

and a 3/4” socket into the top end of the bar |

|

16. Now reinstall the Running

Gear Assembly back on the bar. I ran the assembly all the way up

to show you how it should look against the Clam-Clevis. |

|

| 17. Install the Foot Piece

on the bar and insert the cotter pin. The longer side of the foot

goes forward on the Jack. |

|

The completed rebuild. |

|

| Don't forget to test the Jack.

Ensure that the reversing latch is latched and just operate the jack.

It should move up smoothly, and when you release the reversing latch

should go crashing to the floor. Remember there is no weight against

it at the moment. |

|

You will need to lubricate

the following points on the Hi-Lift.

- Steel Bar

- Pitman Pin

- Shear Bolt

- Climbing Pins and Springs

|

|

| |

| Daystar Handle Holder |

During my recent overhaul of my Hi-Lift Jack I snapped the old rusted handle holder. Not much of a loss really, I had been using some bungee straps to hold the handle from rattling and flailing about. I looked around for another way to hold the handle. Hi-Lift makes a holder and so does Daystar. I was able to get a Daystar holder for really (free) cheap so I decided to use it on my Hi-Lift Jack. There is a difference between the two holders. With the Daystar you need to remove the top clamp slide the holder on and then reinstall the clamp. With the Hi-lift holder, you can slide it right over that top clamp.

NOTICE: IT IS VERY IMPORTANT FOR THE HANDLE-KEEPER TO BE REMOVED DURING JACK USE TO ALLOW THE HANDLE TO BE PLACE IN THE FULL UPRIGHT POSITION AS STATED IN THE HI-LIFT SAFETY INSTRUCTION MANUAL. |

Here is what it looks like. You can get them in various colors. Yellow, Red, Black. If I remember correctly. |

|

| 1. Remove the Top Clam-Clevis by removing the Top Clam-Clevis Bolt

with a 3/4” combo wrench and a 3/4” socket. It’s

easier if you can clamp this in a vice, but I managed to lock a

leg around it and get it to come free. |

|

|

| 2. Slide the handle holder down over the top of the bar. |

|

|

| 3. Slide the handle holder over the handle. |

|

|

| 4. Install the Clam-Clevis

by installing the Top Clam-Clevis Bolt with a 3/4” combo wrench

and a 3/4” socket into the top end of the bar |

|

| Remember every time you need to use this Hi-Lift you will need to remove that top clamp and remove the holder. With that in mind I would recommend going with the Hi-Lift holder if you consistently use that top clamp. I have the Jack Mate, so I only have the clamp on for the pictures. |